Hyundai Ioniq: Timing System / Timing Chain Cover. Repair procedures

Hyundai Ioniq (AE) 2017-2025 Service Manual / Engine Mechanical System / Timing System / Timing Chain Cover. Repair procedures

| Removal |

Engine removal is not required for this procedure.

|

|

|

| 1. | Shut off the High Voltage circuit. (Refer to General Information - "High Voltage Shutoff Procedure") |

| 2. | Disconnect the battery negative terminal. |

| 3. | Loosen the drain plug, and drain the engine oil. Remove the oil filter cap to help drain the engine oil faster. (Refer to Lubrication System - "Engine Oil") |

| 4. | Remove the air cleaner assembly. (Refer to Intake And Exhaust System - "Air Cleaner") |

| 5. | Remove the RH front wheel. (Refer to Suspension System - "Wheel") |

| 6. | Remove the engine room under cover. (Refer to Engine And Transaxle Assembly - "Engine Room Under Cover") |

| 7. | Remove the drive belt. (Refer to Timing System - "Drive Belt") |

| 8. | Remove the engine mounting support bracket. (Refer to Engine And Transaxle Assembly - "Engine Mounting") |

| 9. | Remove the engine support bracket.

|

| 10. | Remove the drive belt tensioner. (Refer to Timing System - "Drive Belt Tensioner") |

| 11. | Remove the idler. (Refer to Timing System - "Idler") |

| 12. | Remove the crankshaft damper pulley. (Refer to Timing System - "Crankshaft Damper Pulley") |

| 13. | Remove the water pump pulley. (Refer to Cooling System - "Water Pump") |

| 14. | Remove the cylinder head cover. (Refer to Cylinder Head Assembly - "Cylinder Head Cover") |

| 15. | Remove the oil control solenoid (OCS) (A) and then remove the timing chain cover (B).

|

| Installation |

| 1. | Install the timing chain cover.

|

| 2. | Install the oil control solenoid (OCS) (A).

|

| 3. | Replace the front oil seal if necessary. (Refer to Timing System - "Front Oil Seal") |

| 4. | Install the other parts reverse order of removal. |

| 5. | Connect the High Voltage circuit. (Refer to General Information - "High Voltage Shutoff Procedure") |

| 6. | Add all the necessary fluids and check for leaks. Connect GDS. Check for codes, note, and clear. Recheck.

|

Other information:

Hyundai Ioniq (AE) 2017-2025 Service Manual: Rear Door Belt Inside Weatherstrip. Repair procedures

Replacement1.Remove the rear door trim.(Refer to Rear Door - "Rear Door Trim")2.Remove the rear door belt inside weatherstrip (A).3.To install, reverse the removal procedure. • When installing, install it by first contacting the inside part (basis point of assembly) of arrow to door frame...

Hyundai Ioniq (AE) 2017-2025 Owner's Manual: Seat Belt Warning Light

Seat belt warning light As a reminder to the driver, the seat belt warning light will illuminate and warning chime will sound for approximately 6 seconds each time you place the Engine Start/Stop button to the ON position if the seat belt is unfastened...

Categories

- Manuals Home

- 1st Generation Ioniq Owners Manual

- 1st Generation Ioniq Service Manual

- Hybrid battery SOC (State of Charge) gauge

- Washer Fluid

- Check Hybrid system, Check Hybrid system. Turn engine Off

- New on site

- Most important about car

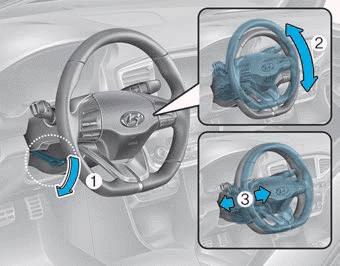

Tilt Steering / Telescope Steering

Adjust the steering wheel so it points toward your chest, not toward your face. Make sure you can see the instrument cluster warning lights and gauges. After adjusting, push the steering wheel both up and down to be certain it is locked in position. Always adjust the position of the steering wheel before driving.

WARNING

NEVER adjust the steering wheel while driving. This may cause loss of vehicle control resulting in an accident.

Copyright © 2025 www.hioniqae.com