Hyundai Ioniq: Hybrid Control System / HPCU (Hybrid Power Control Unit). Repair procedures

Hyundai Ioniq (AE) 2017-2025 Service Manual / Hybrid Control System / Hybrid Control System / HPCU (Hybrid Power Control Unit). Repair procedures

| Removal |

|

Hybrid Power Control Unit (HPCU)

| 1. | Shut off the high voltage circuit. (Refer to Hybrid Control System - "High Voltage Shutoff Procedure") |

| 2. | Remove the air cleaner assembly and air duct. (Refer to Engine Mechanical System - "Air Cleaner") |

| 3. | Remove the ECM & TCM bracket assembly. (Refer to Engine Control/Fuel System - "Engine Control Module") |

| 4. | Drain the coolant of hybrid motor cooling system. (Refer to Hybrid Motor Cooling System - "Coolant") |

| 5. | Disconnect the motor power cable connector (A) and HSG power cable connector (B) after loosening the mounting bolts.

|

| 6. | Disconnect the power cable (A) and inverter power cable (B) from the HPCU.

|

| 7. | Disconnect the HCU & inverter (MCU) connector (A).

|

| 8. | Disconnect the coolant outlet hose & pipe after loosening the mounting bolt (A).

|

| 9. | Disconnect the coolant inlet hose quick-connector (A). |

| 10. | Remove the LDC power outlet cable mounting bolt (B) and ground cable bolt (C).

|

| 11. | Remove the HPCU (A) after loosening the mounting bolts.

|

| Installation |

|

| 1. | Install the HPCU in the reverse order of removal.

|

| 2. | Refill the hybrid motor cooling system coolant and perform air bleeding by using the GDS. (Refer to Hybrid Motor Cooling System - "Coolant")

|

HCU Variant Coding

| 1. | Turn the ignition switch OFF. |

| 2. | Connect the KDS / GDS to Data Link Connector (DLC). Turn the ignition switch ON. |

| 3. | Select "Vehicle, Model year, Engine, System". |

| 4. | Select "Vehicle S/W Management". |

| 5. | Select "HCU Variant Coding".

|

Engine Clutch / Motor Resolver Adaptation

| 1. | Turn the ignition switch OFF. |

| 2. | Connect the KDS / GDS to Data Link Connector (DLC). Turn the ignition switch ON. |

| 3. | Select "Vehicle, Model year, Engine, System". |

| 4. | Select "Vehicle S/W Management". |

| 5. | Select "Engine clutch/motor resolver adaptation.".

|

HPCU (Hybrid Power Control Unit). Components and components location

HPCU (Hybrid Power Control Unit). Components and components location

Components1. Hybrid Control Unit (HCU)2. Inverter3. Low DC/DC Converter (LDC)4. Connector (↔ High Voltage Battery)5. Connector (↔ Motor)6. Connector (↔ HSG)7...

HCU (Hybrid Control Unit). Schematic diagrams

HCU (Hybrid Control Unit). Schematic diagrams

HCU Terminal and Input / Output SignalTerminal FunctionConnector [C133-S]

Pin No

Description

Connected to

1HCU GroundChassis ground2HCU GroundChassis ground3HCU GroundChassis ground4Battery power (B+)Battery5Battery power (B+)Battery6Battery power (B+)Battery7- 8- 9- 10- 11- 12- 13- 14- 15Brake Switch 2 signal inputBrake Switch (NC, IG1)16Brake Switch 1 signal inputBrake Switch (NO, B+)17- 18- 19- 20- 21- 22- 23- 24- 25- 26- 27- 28- 29- 30- 31-32-33-34- 35- 36- 37- 38Start signal inputSmart Key Unit39- 40- 41- 42- 43- 44- 45- 46- 47- 48- 49- 50- 51- 52- 53- 54- 55- 56- 57- 58- 59- 60- 61- 62- 63- 64- 65- 66- 67- 68- 69- 70- 71- 72- 73IGN signal inputSmart Key Unit74- 75- 76- 77- 78Powertrain CAN [High] signal inputOther control modules79Powertrain CAN [Low] signal inputOther control modules80- 81Hybrid CAN [High] signal inputOther control modules82Hybrid CAN [Low] signal inputOther control modules83- 84- 85- 86- 87- 88- 89- 90- 91- 92- 93- 94- Input/Output signalConnector [C133-S]

Pin no

Description

Condition

Type

Level

1HCU GroundAlwaysDC VoltageMax...

Other information:

Hyundai Ioniq (AE) 2017-2025 Owner's Manual: Power adjustment

The front seat can be adjusted by using the control switches located on the outside of the seat cushion. Before driving, adjust the seat to the proper position so that you can easily control the steering wheel, foot pedals and controls on the instrument panel...

Hyundai Ioniq (AE) 2017-2025 Service Manual: Engine Coolant Temperature Sensor (ECTS). Repair procedures

Inspection1.Turn the ignition switch OFF.2.Remove the ECTS.(Refer to "Removal")3.After immersing the thermistor of the sensor into engine coolant, measure resistance between the ECTS terminals 1 and 3.4.Check that the resistance is within the specification...

Categories

- Manuals Home

- 1st Generation Ioniq Owners Manual

- 1st Generation Ioniq Service Manual

- How to Disconnect Normal Charger

- Auto Door Lock/Unlock Features

- Checking the Coolant Level

- New on site

- Most important about car

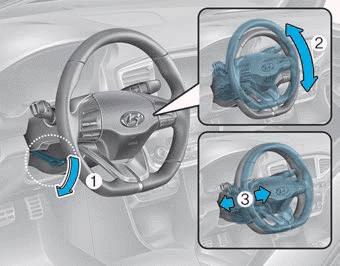

Tilt Steering / Telescope Steering

Adjust the steering wheel so it points toward your chest, not toward your face. Make sure you can see the instrument cluster warning lights and gauges. After adjusting, push the steering wheel both up and down to be certain it is locked in position. Always adjust the position of the steering wheel before driving.

WARNING

NEVER adjust the steering wheel while driving. This may cause loss of vehicle control resulting in an accident.

Copyright © 2025 www.hioniqae.com