Hyundai Ioniq: Brake System / Front Disc Brake. Repair procedures

Hyundai Ioniq (AE) 2017-2025 Service Manual / Brake System / Brake System / Front Disc Brake. Repair procedures

| Removal |

| 1. | Loosen the wheel nuts slightly. Raise the vehicle, and make sure it is securely supported. |

| 2. | Remove the front wheel and tire (A) from the front hub.

|

| 3. | Loosen the brake hose mounting bolt and then remove the brake hose bracket.

|

| 4. | Put down the caliper body after loosening the guide rod bolt.

|

| 5. | Remove the pad return spring (A).

|

| 6. | Remove the brake pad.

|

| 7. | Separate the pad retainer. And remove the caliper carrier by loosening the caliper mounting bolts.

|

| 8. | Remove the front brake disc by loosening the screws.

|

| Replacement |

Brake Pad

| 1. | Loosen the wheel nuts slightly. Raise the vehicle, and make sure it is securely supported. |

| 2. | Remove the front wheel and tire (A) from the front hub.

|

| 3. | Loosen the brake hose mounting bolt and then remove the brake hose bracket.

|

| 4. | Put down the caliper body after loosening the guide rod bolt.

|

| 5. | Remove the pad return spring (A).

|

| 6. | Remove the brake pad.

|

| 7. | Install the pad return spring (A).

|

| 8. | Use a SST (09581-2T100) when installing the brake caliper assembly.

|

| 9. | Install the caliper body (A) then tighten the guide rod bolt (B).

|

| Inspection |

Front Brake Disc Thickness Check

| 1. | Check the brake pads for wear and fade. |

| 2. | Check the brake disc for damage and cracks. |

| 3. | Remove all rust and contamination from the surface, and measure the disc thickness at 24 points, at least, of same distance (5mm) from the brake disc outer circle.

|

| 4. | If wear exceeds the limit, replace the discs and pad assembly left and right of the vehicle. |

Front Brake Pad Check

| 1. | Check the pad wear. Measure the pad thickness and replace it, if it is less than the specified value.

|

| 2. | Check that grease is applied, to sliding contact points. Check for metal damage to the pad and backing.

|

Front brake disc runout check

| 1. | Place a dial gauge about 10mm (0.2 in.) from the outer circumference of the brake disc, and measure the runout of the disc.

|

| 2. | If the runout of the brake disc exceeds the limit specification, replace the disc, and then measure the runout again. |

| 3. | If the runout does not meet the limit specification, remove the disc, turn it 180° and reinstall. Then check the runout of the brake disc again. |

| 4. | If the runout cannot be corrected by changing the position of the brake disc, replace the brake disc. |

| Installation |

| 1. | To install, reverse the removal procedure. |

| 2. | Use a SST (09581-2T100) when installing the brake caliper assembly.

|

| 3. | After installing, bleed the brake system. (Refer to Brake System - "ESP System Bleeding") |

Rear Disc Brake. Components and components location

Rear Disc Brake. Components and components location

Components[EPB None Apply]1. Brake pad2. Pad return spring3. Caliper carrier4. Pad retainer5. Caliper body6. Bleed screw7. Stopper8. Return spring9. Operating lever[EPB Apply]1...

Other information:

Hyundai Ioniq (AE) 2017-2025 Service Manual: Description and operation

DescriptionThe VESS (Virtual engine sound system) generates engine sound when you start the hybrid system.This sound is for pedestrians to hear vehicle sound because there is no engine sound in hybrid driving.VESS operates when vehicle speed is between 0...

Hyundai Ioniq (AE) 2017-2025 Owner's Manual: Air conditioning refrigerant label

The actual Air Conditioning refrigerant label in the vehicle may differ from the illustration. Each symbols and specification on air conditioning refrigerant label means as below : 1. Classification of refrigerant 2. Amount of refrigerant 3. Classification of Compressor lubricant Refer to chapter 8 for more detail location of the air conditioning refrigerant label...

Categories

- Manuals Home

- 1st Generation Ioniq Owners Manual

- 1st Generation Ioniq Service Manual

- High Beam Assist (HBA)

- If the 12 Volt Battery is Discharged (Hybrid Vehicle)

- Coasting Guide (Plug-in hybrid vehicle)

- New on site

- Most important about car

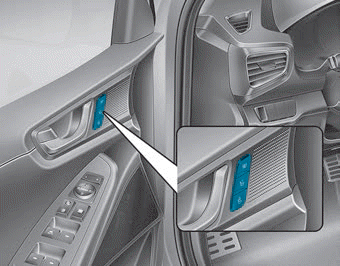

Driver Position Memory System

The Driver Position Memory System is provided to store and recall the following memory settings with a simple button operation.

- Driver's seat position

- Side view mirror position

- Instrument panel illumination intensity

Copyright © 2025 www.hioniqae.com